Gallery

Carbon Fiber Wrapping Service in Dubai

Video gallery

Price

Reviews

write a reviewRelated Services

Our Team

Carbon fiber lamination is an upgrade that most car owners and car enthusiasts are looking for. The trend toward carbon fibre cars is no longer limited to high-end sports cars; it has gone far beyond and transitioned to a broader luxury vehicle segment, reflecting a growing appreciation for the material’s light weight, strength, durability, and aesthetics.

As Dubai’s climate and urban environment demand materials that can withstand heat, UV exposure, and wear, carbon fiber laminates offer an ideal solution. But to achieve flawless results, the procedure must be observed and high-quality materials have to be used. Today’s article explains why carbon fiber lamination is becoming a trend in Dubai, gives an overview of its applications, and describes the lamination process in detail.

What Is Carbon Fibre Laminate and What Makes the Honeycomb Pattern Trendy?

Carbon fibre is a high-performance composite material made by weaving extremely fine strands of carbon into fabric, commonly known as carbon composite fibre cloth. These strands are reinforced and bonded together within an epoxy resin matrix to create a laminated composite that is both exceptionally strong and lightweight. The outstanding mechanical properties of carbon fibre, such as high tensile strength, superior stiffness, and excellent thermal resistance, make it an ideal material for automotive applications where performance and appearance are critical.

Carbon fibre is also UV stable and corrosion-resistant. These are essential qualities for vehicles exposed to Dubai’s sun and sandstorms. The low weight of the material enhances vehicle dynamics, improving acceleration, handling, and fuel efficiency — key factors for sports cars and luxury automobiles.

The lamination process involves a wet layup of multiple layers of carbon fibre cloth, typically using conventional weave patterns like twill 3k carbon fibre or 2×2 twill, applied onto a carefully prepared surface. The fabric is impregnated with epoxy resin mixed with a hardener and then cured to form a durable, precise surface finish.

Techniques such as vacuum bagging are employed during curing to ensure the carbon fibre conforms accurately to the part’s geometry, eliminating air bubbles and imperfections. Alternatively, prepreg materials — pre-impregnated with resin — may be used for enhanced consistency. This process of making carbon fibre parts results in a lightweight, reinforced component with superior mechanical properties and an impeccable surface finish.

Using Carbon Fibre Lamination: Various Applications for sports and Luxury Cars

Car owners in Dubai use carbon fibre lamination widely for both cosmetic and structural upgrades:

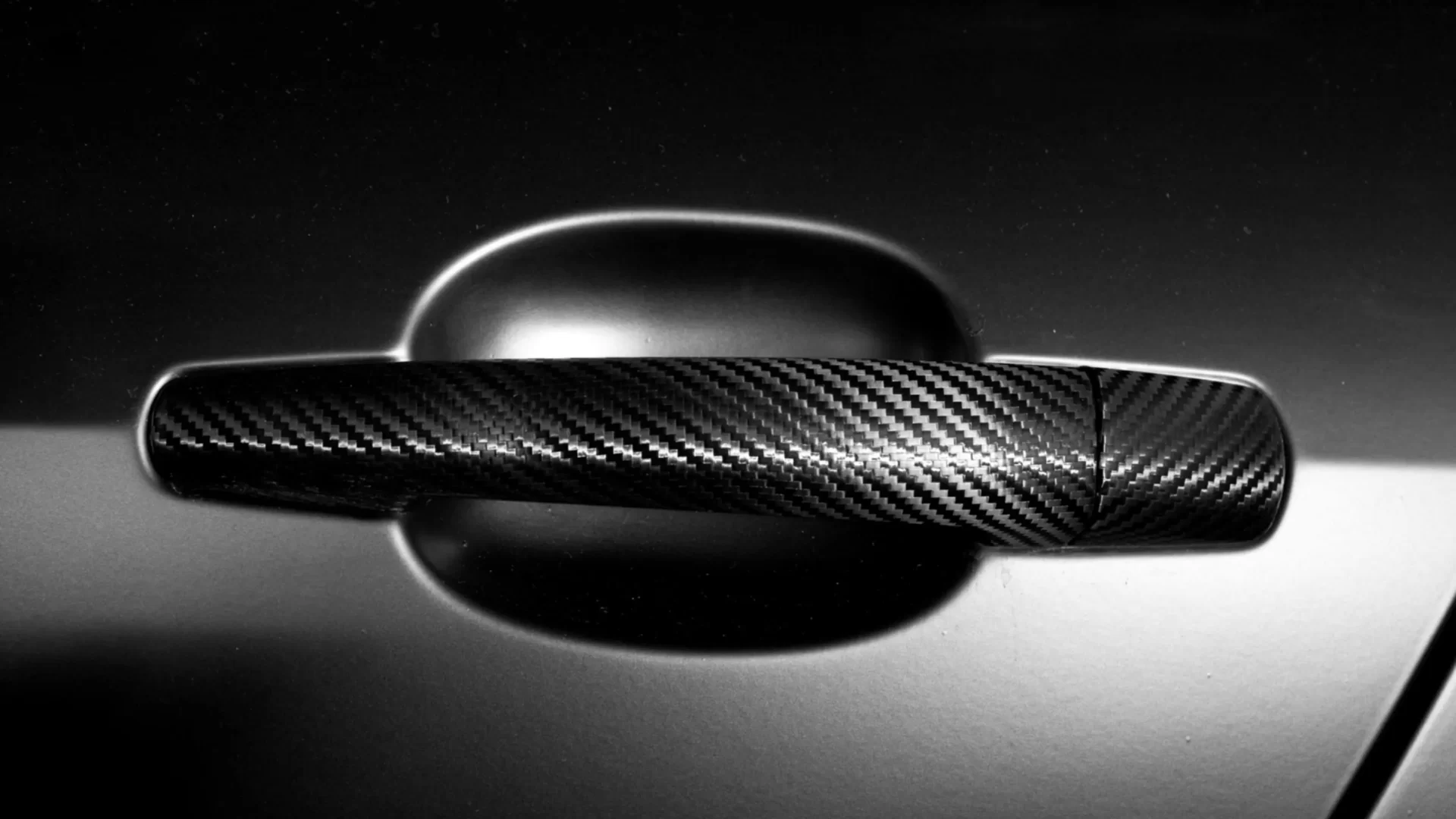

- Interior Components: Carbon fiber laminated onto dashboard trims, center consoles, door panels, steering wheels, and gear knobs provides a premium, sporty look. Using twill 3k carbon fibre cloth and EL2 epoxy laminating resin with hand laminating brushes ensures that these parts gain excellent mechanical properties.

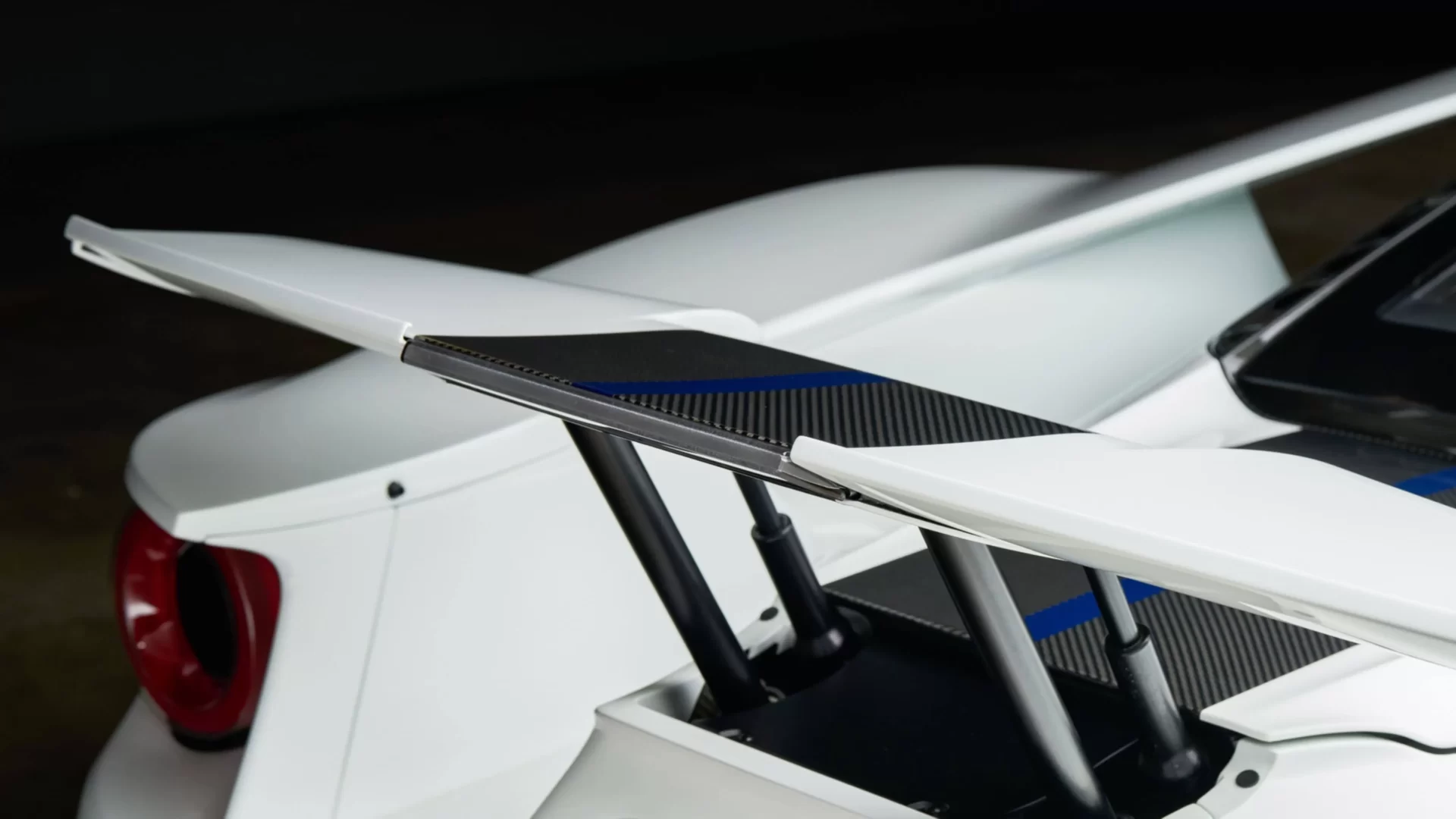

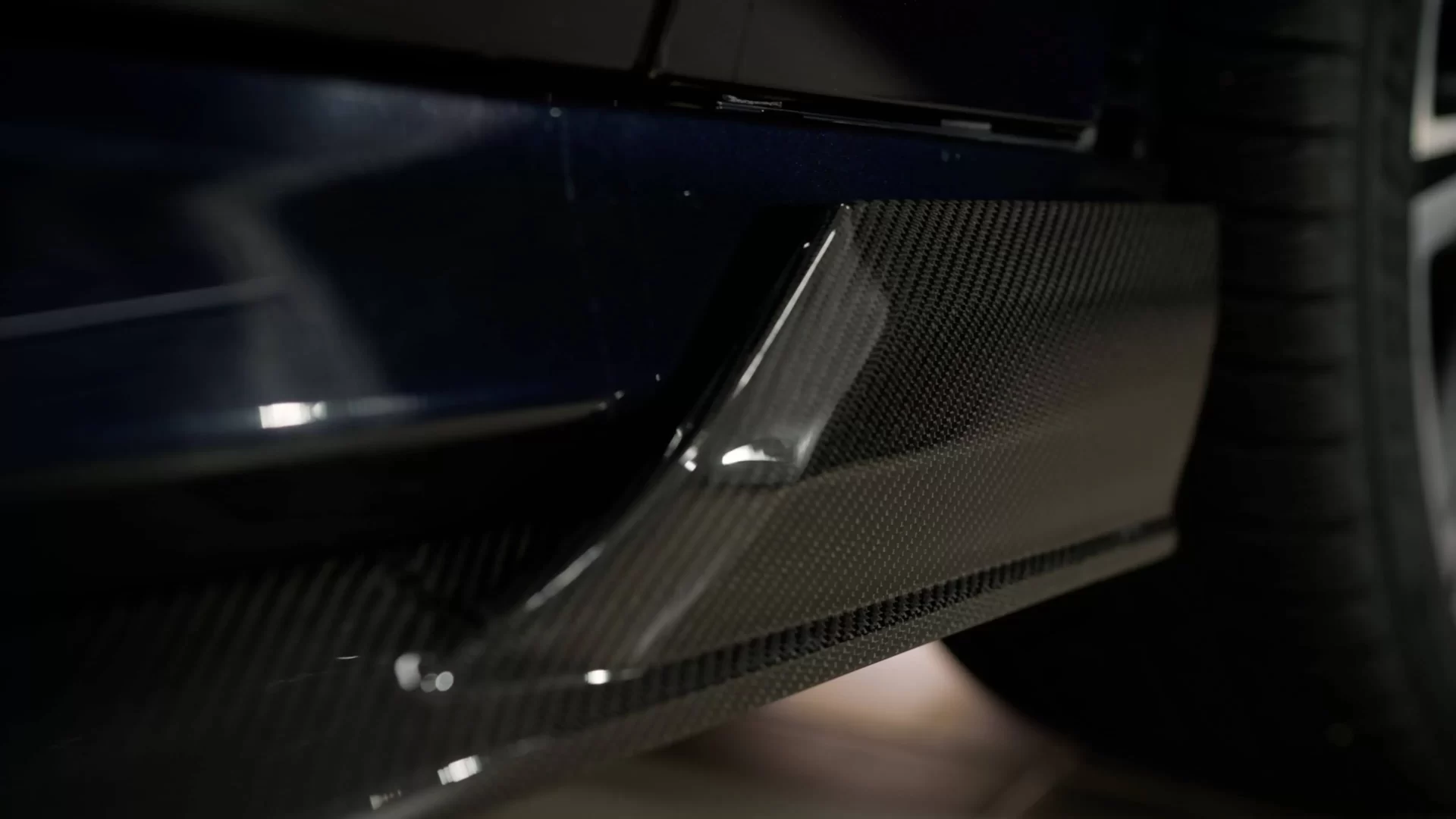

- Exterior Components: Laminating carbon fiber on side mirrors, spoilers, splitters, and moldings increases stiffness and reduces weight, improving aerodynamics and performance. The wet layup process combined with vacuum bagging or RTM ensures precise adhesion to complex shapes, free of air bubbles and imperfections.

- Structural Reinforcement: Carbon fibre adds strength and durability over plastic or metal surfaces, enhancing impact resistance, scratch protection, and heat resistance, which is key for Dubai’s harsh climate.

- Personalization: Customers can choose from weave patterns like twill, 2×2 twill, or spread tow, and finishes such as matte, satin, or high-gloss. A carbon fibre laminating starter kit contains carbon fibre cloth, epoxy resin, and ancillary tools to create customized laminated composites.

For those who want to get the look and performance of carbon fibre without full part replacement, laminating carbon fiber is a cost-effective, high-strength solution that improves stiffness, reduces weight, and delivers a premium surface finish.

Our Carbon Fibre Lamination Process

Desert Diamond creates top-quality carbon fibre laminates using a controlled and accurate process:

- Consultation and Element Selection. Our process begins with a comprehensive consultation in an attempt to identify the customer target, vehicle model, and parts to laminate. We will suggest the most appropriate form of carbon fibre fabric and resin system based on the intended function of the finished part along with exposure.

- Surface Preparation. We degrease and sand the surface of the final part thoroughly in such a way that no residual contaminant remains, providing optimal adhesion to the carbon fibre laminate. This prevents problems such as bubbling or peeling.

- Laminating Carbon Fiber. Using either our standard hand layup or optimized vacuum infusion process, we wet-out individual plies of carbon fibre cloth onto the product. The material is then wetted-out with EL2 epoxy laminating resin and a predetermined amount of hardener to control the pot-life (the amount of time the mixed material remains usable and workable) and curing sequence.

- Vacuum bagging stands for wrapping a vacuum bag around the part and removing air to compress the laminate firmly, boil off excess resin, and force out air bubbles. This creates a high fiber volume fraction and lightweight, rigid laminate.

- Curing and Finishing. The resin is then allowed to cure in controlled temperature and humidity-controlled chambers to acquire its final mechanical strength. The part is then wet sanded and polished to buff off any minor surface imperfections.

Finally, we apply a clear coat or UV-resistant lacquer to finish sealing the part and provide the surface with the desired finish — either glossy for the showroom look or matte for the stealth effect.

Why Choose Desert Diamond for Composite Carbon Fibre Lamination?

Desert Diamond is Dubai’s premier carbon fibre lamination facility due to the following:

- High Experience: We have experience with working on different high-performance sports cars and luxury cars. We are well aware of the complex geometries of the surface of the parts you may wish to laminate.

- Hand Lamination Techniques: Our professionals utilize accurate hand laminating brushes and techniques, so that each carbon fibre layer and resin is applied to place exactly according to the weave pattern without any distortion or creasing.

- Personal Solutions: From custom carbon fibre part design to factory parts laminating, we develop solutions for all your needs. Through our mold-making capacity and CNC machine shop, we can produce intricate geometries and specialty components.

- Quality Material: We only use original carbon fibre fabric — such as twill 3k carbon fibre — and high-quality epoxy resin that possess good mechanical strengths, and is UV and heat-resistant.

- Variety of Carbon Fibre Types: We offer a lamination in woven and forged carbon fibre, depending on the reinforcement paramenter you require, as well as on your aesthetic needs. Woven composite carbon fibre is made of fine strands woven into a particular pattern of fabric (high-plain weave or twill). It is prized for its classic look and strength. Forged composite carbon fibre is made from chopped carbon fibers mixed with resin and compressed into molds, resulting in a unique marbled appearance and lighter weight, with excellent strength but a different texture and visual effect.

- Defect-Free Studio Environment: At our studio, we eliminate typical lamination defects, like ‘air bubbles,’ resin pool, or uneven curing. Using release agents and PVA ensures parts are removed from the moulds cleanly.

Custom Carbon Fibre Parts Manufacturing and Styling Solutions

For customers who wish to customize their vehicles and create carbon fiber parts, Desert Diamond offers the entire set of custom parts manufacturing and styling solutions:

- From Factory Parts to Moulding: Vehicle parts may be laminated or new parts fabricated from prepreg carbon fibre (fibre pre-impregnated with resin) or by the wet-lay process.

- Integration with Other Tuning Components: Carbon fibre laminates may be combined with FRP (fiberglass reinforced plastic) or honeycomb cores (composite fillers used for manufacturing carbon fiber that is advanced in terms of strength and stiffness) for body panel and structure component weight reduction.

- Sport and Luxury Design Aesthetic: You may need a spread tow weave with the new look or aclassic twill pattern — our styling solutions are designed to make your vehicle stand out.

- State-of-the-Art Process Techniques: With autoclave curing and RTM (resin transfer molding), we produce parts with enhanced surface finish and mechanical properties.